Akademie

- 4. blok - System diagnosis

- Emission systems (počet lekcí: 0)

DPF - FAP filter (Wall Flow) - How they work?

Úvod

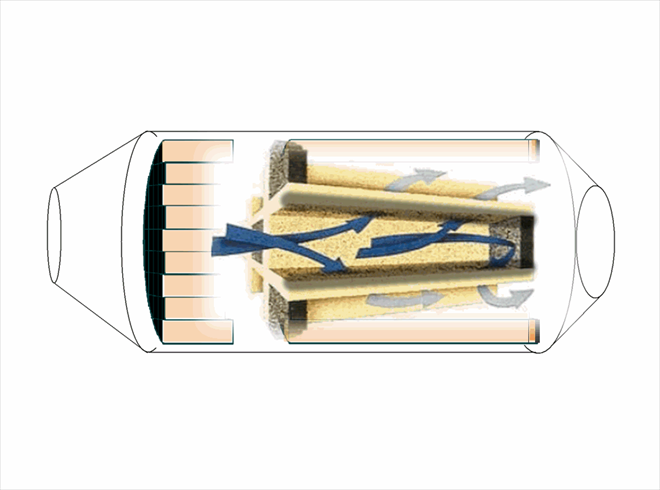

Closed particulate filter (Wall Flow)

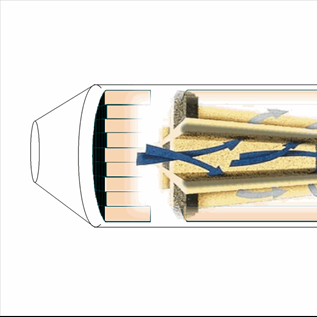

This type of filter doesn't allow almost any microsoot particles to pass through. The cells that are plugged at one end and open at the opposite side, force the exhaust gas to flow through its porous walls and trap the particulate matter. If we were to unfold these cells on a passenger car filter the overall area would be bigger than 2.4 m3 (similar to the size of a vacuum cleaner filter bag). The exhaust gas flow restriction is very low. If the engine is OK, it produces a very small amount of smoke (soot generation) anyway and only in driveaway modes.

The task of closed particulate filters:

On modern high pressure injection engines the higher the injection pressure the smaller the soot particles are. This means that these engines generate the smallest and thus the most dangerous exhaust particles, that can penetrate from the lungs to the blood and even to the brain. The particulate filters function is to trap the soot generated mainly during city and cold engine operating modes and to burn them off almost completely in the filter during periodic intervals (around 600 km). The filter together with the catalytic converter not only traps the particles but also removes them here in the most environmental friendly way. This is if everything works as it should.

Regeneration methods (two basic methods)

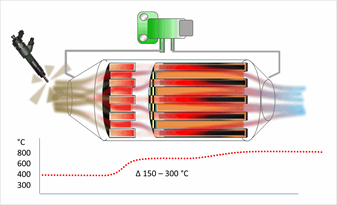

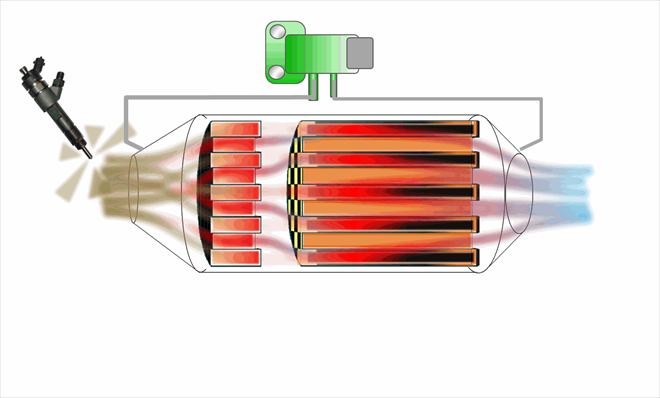

1. Dry method - the particulate filter is burned out by increasing the exhaust temperature to 570 - 700 °C, by activating post injections when the piston position is after TDC (or by injecting fuel into the exhaust by an independent injector) without any other support.

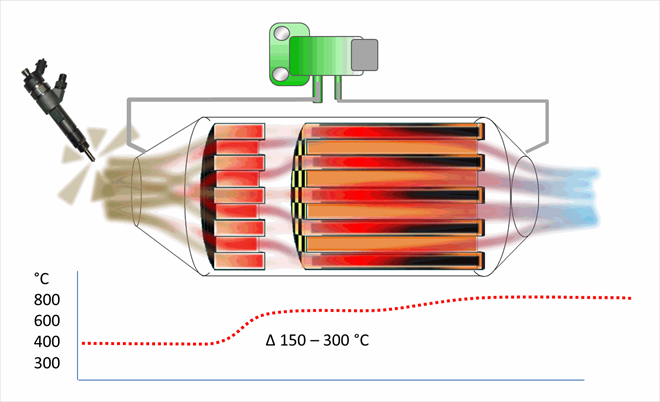

2. Wet method - an additive is injected into the fuel tank during every refueling (e.g. EOLYS or SATACEN), that is soluble with diesel fuel and the generated soot from this has the ability to burn rapidly at temperatures around 420 °C. The additive reduces the soot combustion temperature by about 150 – 200 °C. If there is no additive in the fuel tank the soot will start to burn at the same temperatures as under the "dry method".

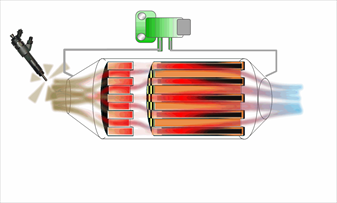

Double task of the oxidation catalytic converter

1. To reduce the emissions of CO and HC and soot in the exhaust gases under normal operating conditions of the engine. The oxidation catalytic converter reduces the volume of soot travelling with the exhaust gases to the DPF filter by almost 30 %. This is under the circumstances that the converter is working correctly, is not contaminated, thermally deteriorated or that the converters "wash coat" hasn't shrunken (gamma alumina > alfa alumina).

2. Increase the temperature of the exhaust gases flowing into the particulate filter during regenerations. This occurs when the ATDC injected fuel contacts the catalytic coated ceramic (metal) grid of the oxidation catalytic converter. During a chemical reaction when HC and CO is converted to CO2 to H2O a large amount of heat is generated (about 450 °C in front of the converter and about 700 °C behind the converter).

Saturated particulate filter symptoms:

– increased fuel economy

– increased engine oil level caused by diesel fuel contamination due to ongoing unsuccessful regeneration attempts

– frequent regenerations

– frequent warning light illumination for high saturation levels of DPF filter

– engine limp-in home condition

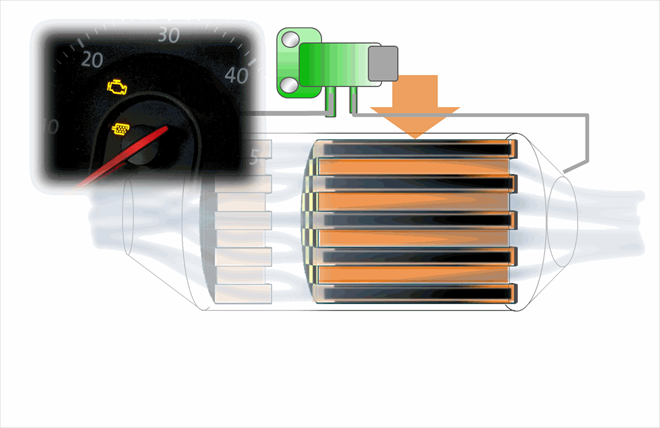

– illumination of DPF filter warning light, sometimes together with the OBD MIL light

Main issues with particulate filters

– unsuitable vehicle usage driving short distances (e.g. permanent driving only in cities)

– deteriorated oxidation catalyst (doesn't generate the required temperatures during regeneration)

– using unsuitable chemicals (fuel additives, DPF chemical cleaners - forbidden)

– refuelling petrol insead of diesel (even 3-5 liters is dangerous)

– defective exhaust pressure and temperature sensors, intake valve closed position sensor

– excessive smoking engine (faulty injectors, intake system leak after the turbocharger, chiptuning, worn out engine

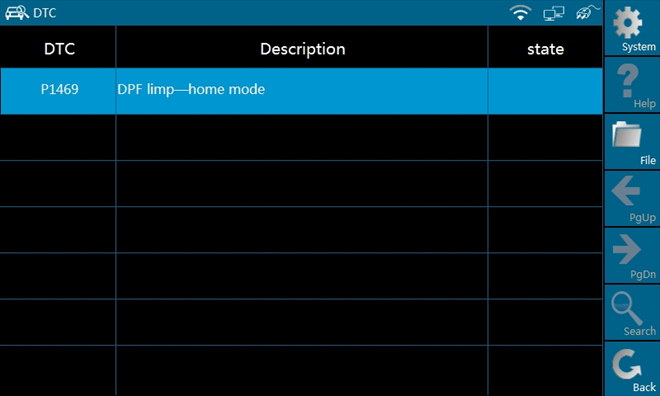

Logged DTC's:

– too high exhaust pressure

– particulate filter – soot (ash) high saturationl rate

– filter efficiency is below threshold

How to diagnose the system is described in article DPF filter – How to diagnose problems

Other problems caused by tampered systems

Modifications of the vehicle are always a problem. Removal of the DPF filter without reprogramming or using an emulator devastates the environment because regenerations occur every 800 km (time preventive regeneration excluding the exhaust system pressure value). Because the values in the control unit are shared with other control units and if a value is changed in one unit the formula will be incorrect and the calculated values will be wrong and can cause unpredictable behaviour. The results can be problems that are almost impossible to solve.

Chiptuning, odometer manipulation, filter removal and control unit reprogramming so that the particulate filter is not seen, including emulators of exhaust pressure and temperature signals can create great diagnostic problems on modern cars with future multiple DTC problems, that can't be corrected without returning the systems to their original condition.

The less complex systems on MY 2000 - 2006 vehicles usually worked when the filter was removed and with the modified software. Nevertheless these system can have problems with diagnostics (missing DTC's). On the most current systems the software is much more interconnected, so for instance odometer manipulation (illegal) can influence the DPF filter saturation level calculation so much that the system will report a full DPF filter after driving only several hundred meters. This can occur even when the exhaust pressure is not at the level of natural regeneration. On these modern systems it is almost impossible to remove the particulate filter without any negative influence on the vehicles behaviour. The particulate filter removal will at some stage show up, with the vehicle having problems like bad engine performance, MIL illumination or limp-in home mode with restricted power.

DPF (FAP) - vše okolo filtrů částic (diesel) (1834/1)

Čím modernější dieselový motor, tím vyšší vstřikovací tlaky a tím menší a nebezpečnější saze ve výfukových plynech. Paradoxně je skoro není vidět. O to důležitější je, aby jejich skoro stoprocentní odfiltrovávání ve výfuku automobilu fungovalo. Někde funguje, ani o něm majitel auta neví. Polovina lidí ho začne mít ráda, až mu zcela a do detailu porozumí.Wall Flow – particulate filter (1834/2)

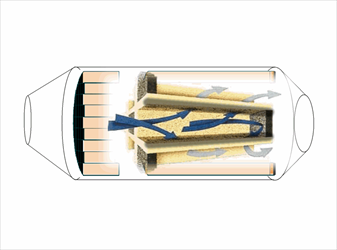

"Wall flow" means that the gas flows through the porous walls. The exhaust gases are filtered similar to a vacuum cleaner that uses the same "Wall Flow" principle. The only difference is that the "wall" is the paper bag surface. The soot deposits on the inner wall from the direction of the cells that are open towards the engine side. The cells from the other side (outer, open towards the exhaust tailpipe) are still completely clean, with no soot present.

Regeneration of the so called "dry" and "wet" system particulate filters (1834/3)

Based on the high pressure signal from the filter because the filter is saturated the control unit begins to regenerate the filter by injecting fuel when the piston reaches the ATDC position. In this situation half of the diesel fuel starts to burn from the already ignited mixture and the second half enters the exhaust system unburnt, but with excess oxygen content in the exhaust. Once the unburnt fuel reaches the catalytic surface of the heated converter a chemical reaction begins (oxidation), that generates a large amount of heat, that ignites the trapped soot in the filter. The soot of the "wet system" ignites at temperatures starting at 470 °C and in the "dry system" at temperatures starting at 570 °C. After the soot ignites the post injection can be canceled, because soot is burning exothermically (the burn rate is controlled only by the supplied oxygen – so that it burns at a condition that is similar to a "grill effect"). If the catalytic converter looses its function soot combustion is difficult.

The main task of the oxidation catalytic converter (1834/4)

When an oxidation converter had a malfunction on vehicles that were only equipped with an oxidation catalytic converter nobody found out. (During emissions testing the converter is not examined, has no influence on engine behaviour, not included in onboard diagnostic verification and the engine control unit doesn't know if it is on the vehicle or not). On vehicles that are equipped with a DPF filter the oxidation converter has a second function that is very important for vehicle operation – securing a clean environment. A trouble-free converter functions as a "burner" in the exhaust system. When the converter comes into contact with unburned fuel and oxygen (post injection of fuel when the piston is ATDC) the chemical reaction generates a large amount of heat (simplified: CO + HC = CO2 + H2O).

Unsuitable driving conditions for cars equipped with a DPF filter (1834/5)

Stop n Go traffic driving, long periods of idle, engine not fully warmed, none or minimum operation on open roads at high speeds. All these are factors that are not ideal for vehicles with a DPF filter. To be more specific it's the filters regeneration process that is influenced causing problems where the start of regeneration is difficult, regeneration is not completed fully and regeneration occurs very frequently.

Exhaust tailpipe on a DPF equipped vehicle at 86 640 km (1834/6)

Particulate filter function, where after 122 regenerations the filter is still in a very good condition. The tailpipe shows no signs of any problem.

Exhaust tailpipe on a DPF equipped vehicle at 112 650 km after chemical cleaning (1834/7)

The filter is cracked, the exhaust is full of soot and chemical cleaning residues. The vehicle has problems, the engine oil is contaminated with diesel fuel.

Exhaust tailpipe on a DPF equipped vehicle at 112 650 km after chemical cleaning – detail (1834/8)

The real cause is low exhaust temperature during regeneration (converter malfunction). The regeneration process is such that the diesel fuel injected into the exhaust ATDC doesn't react and unburned is emitted out off the exhaust. Due to low regeneration temperatures in the exhaust the control unit is expecting higher temperatures, that do not occur because the converter is degraded. The long and repeated unsuccessful regeneration's are the cause why the engine oil is being dilluted by diesel fuel.

DPF filter warning light illumination or the MIL light illumination (1834/9)

If the filter warning light keeps turning on it is a notice that a regeneration mode should be performed (usually described in the owner's manual). If next to the illuminated DPF filter warning light the MIL light is also active it is a clear sign that there is an engine or exhaust system malfunction that should be diagnosed as accurately as possible and repaired. A blocked DPF filter is always a result of another problem.

Exhaust tailpipe on a vehicle with defective/removed DPF filter (1834/10)

If the particulate filter is cracked the tailpipe will show signs of ashes that you can wipe out with your finger. If your finger gets dirty you know that the filter is defective or that the DPF filter has been removed.

Petrol in diesel fuel will thermally damage the converter and also the DPF filter (1834/11)

If a diesel engine vehicle is filled up with petrol, it is possible that during a regeneration cycle, unburned petrol can contaminate the diesel and air mixture during post injections. The petrol reacts with the oxidation catalytic converter in a similar way like diesel fuel with the only difference that the burning temperature with oxygen will reach 1500–2000 °C and the converter will usually get damaged and will break up (presence of powder like fragments from the non existent converter in the removed DPF filter). When we take a close look inside the DPF filter we will discover that it has been thermally damaged and is starting to break up. The exhaust tailpipe is black from ashes and thus the result is clear – The DPF filter and the catalytic converter require replacement.

Measures to prevent refuelling of petrol into diesel engine vehicles (1834/12)

It is almost impossible to fill diesel fuel into a petrol engine vehicle (smaller diameter filler neck), but the other way around it is possible. The smaller diameter pump nozzle fits the large diameter filler neck of a diesel engine without a problem. For this reason some manufacturers are starting to install a blocker to the filler neck, so that no other pump nozzle fits. This means that only the the exact diameter of the diesel fuel nozzle will fit and open the blocker and unlock the filler neck (e.g. BMW 325 d 3.0, MY 2006).

Example of problems created only by altering the odometer value (illegal) (1834/13)

Subaru Impreza diesel with particulate filter that is OK, but the problems started when odometer value was altered.

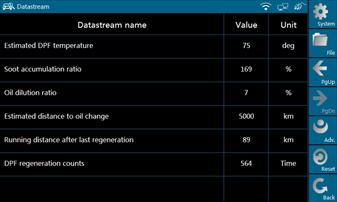

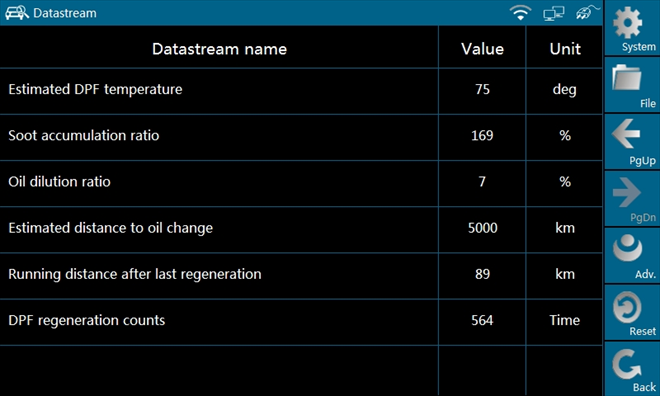

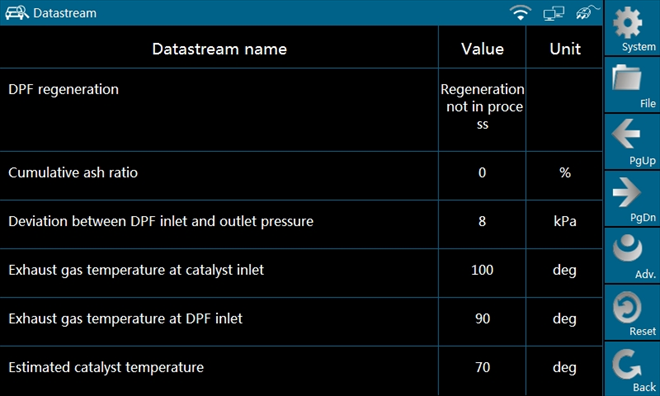

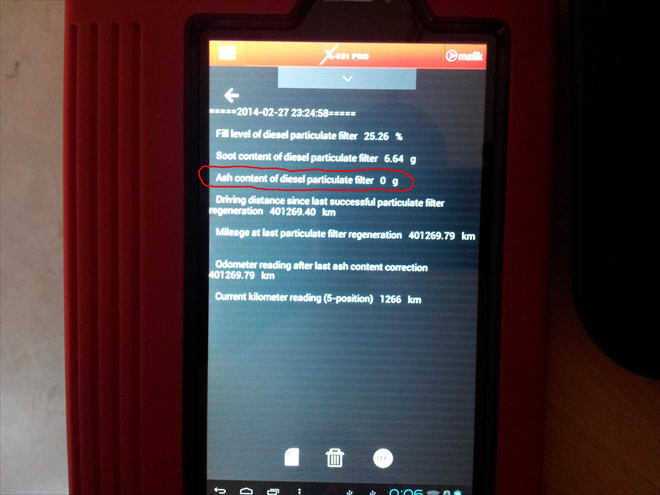

Irrational requests for regeneration, even though its not required (1834/14)

Subaru Impreza - manipulation with odometer value - the accumulation of soot is showing that the saturation rate of the filter is 169% - the distance driven since last regeneration is 89 km - the number of regenerations on this vehicle and this filter = 564 x. Note: At this moment the values of the differential pressure in the particulate filter are 0–4 hPa at idle and about 12 hPa at 2 000 rpm. The filter is actually almost empty and it doesn't contain a high volume of nonburnable ash.

Basic setting to reset zero soot value (1834/15)

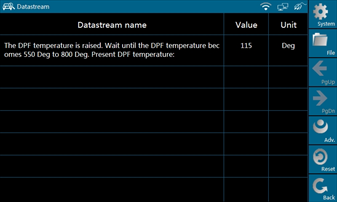

Screenshot that shows a successful reset of the zero soot value in the filter (particulate filter replace/clean function). From this point on you only need to drive less than one kilometer in order for the filter fill value to reach the indicated 160%, for the warning light to turn on and the vehicle to enter the limp-in mode.

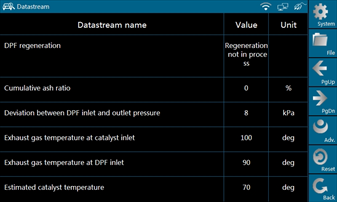

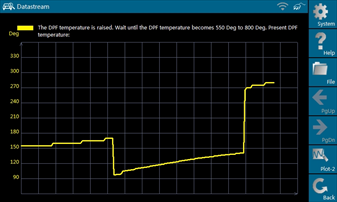

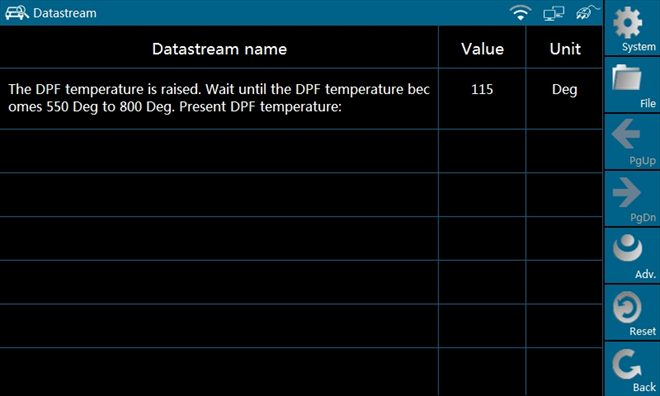

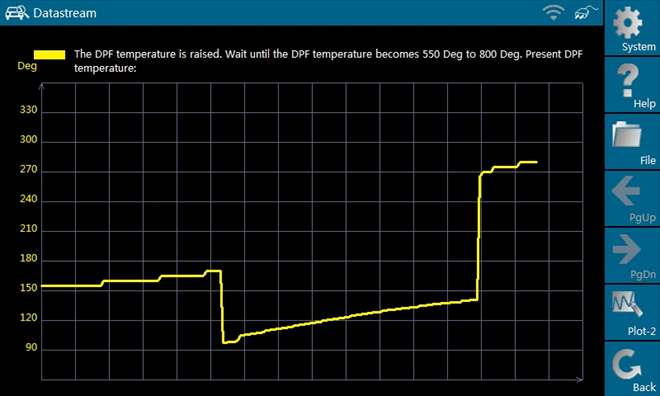

Activation of diagnostic tool service regeneration (1834/16)

The diagnostic tool activation of service regeneration was successful, but....

Software algorithm fault and mixed data in the control unit (1834/17)

Once the regeneration was activated the temperature in the exhaust started to rise due to ATDC injection of diesel fuel. After about 10 seconds the temperature value jumped to temperatures lower by about 100 °C and after another 60 to 80 seconds the regeneration was interrupted because of unfavourable development of temperatures of the catalytic converter and in the particulate filter. Immediately after the regeneration is interrupted the temperature jumps back to the correct relevant temperature. This repeats during every regeneration attempt. Regeneration is not possible. The vehicle after this attempt jumps into limp-in mode and a message that the filter is full (fill rate 179%) is stored in memory.

Myth: During regeneration the vehicle must travel at a minimum speed of 40 km/h (1834/18)

Service regeneration has never been performed on this vehicle. Because this is our company vehicle we are monitoring the natural regenerations. If the regeneration has been activated (the 40–50 km/h is a limit for activating regeneration) it is active even when the vehicle is going downhill without a depressed accelerator pedal, also when the vehicle stops at a junction or traffic lights, etc. The regeneration is not interrupted by slow driving or a short stop. Even when you interrupt your trip and stop at a petrol station for an ice cream the activated regeneration before the stop will continue after the stop. If the vehicle has stopped with the engine running the regeneration temperature is so high that the paint coat above the exhaust tailpipe starts softening (see picture).

I warn not to open the luggage compartment with the engine running, because if you are wearing shorts the hair on your legs will burn and you may even sustain more severe injuries. Apart from other symptoms a regenerating system can be identified by activated cooling fans and increased engine speed at idle. After the vehicle is stopped the complete exhaust system is producing cracking sounds. These are the signs of an active regeneration.

The symptom "increasing engine oil level" is typical for more than one problem.... (1834/19)

If a DPF equipped vehicle has problems with increasing engine oil level, this is a clear sign that the vehicle sometimes regenerates very frequently but in particular it means that regeneration is active for unnecessarily long times. This means that one regeneration can come after 800 km (or longer) after the previous but takes a very long time to complete.

These could be the causes:

– cracked or manipulation with the filter or its system (low pressure in the exhaust before and after regeneration makes the control unit think, that the filter content during regeneration doesn't decrease and this is why it is active for such a long time)

– defective temperature sensor in the exhaust (the control unit is thinking that it cannot achieve the temperature, because the sensor is showing a lower temperature)

– deteriorated converter (during regeneration it cannot increase the temperature in the exhaust to the required value)

– incorrectly performed diagnostics (somebody in a workshop, for example after chemical cleaning set the ash content to zero and it doesn't match the actual state). As a result of this, frequent regenerations occur due to the high ash content that takes up the place of soot

– differential pressure emulator (if DPF/FAP filter illegally removed) that doesn't emulate saturation cycles, but only the same pressure values according to engine speed (fraud)

– other engine problem, not in the DPF/FAP filter system

Witness of excessive smoke – DTC "exhaust gas low flow" (1834/20)

This fouled EGR valve is indicating that regeneration is occuring more frequently. Engines that smoke only a little will show this kind of fouling at around 150 000 km or more. If the engine is in bad shape, the vehicle has unprofessional chiptuning or the engine is worn out, this level of fouling will occur within several months of operation.

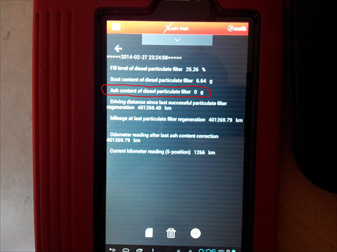

Incorrect diagnosis by previous workshop (1834/21)

Original particulate filter, several attempts to bring vehicle out off limp-in mode and set soot value to zero, so that an invoice can be presented to the customer. But!! If the particulate filter was not replaced, if the DPF filter was not cleaned at all or cleaned only incompletely with chemicals, then the filter content is never zero. This is the most common fault, that is done unknowingly by the workshops, because from this point the ECU is calculating with the fact that regeneration will be ending at a low value of back pressure. This is not the case, because the particulate filter is not completely empty. The algorithms start adapting erratically and this is the start of all the problems.

This vehicle has 401 269 km on the odometer (Mercedes Benz Sprinter) and the particulate filter repeatedly saturates with soot. Unfortunately the previous workshops effort was only to get the vehicle moving as quickly as possible so that an invoice could be issued, but the vehicle also has many DTC's in memory. The DTC's relate for example that two cylinders have glow plug problems or the engine is running irregularly due to big differences in fuel injection amounts. So the vehicle is not in a good condition. By the way this is one complex reason of "limp-in mode" conditions, that the owners are complaining about. No investments into technical condition and only driving doesn't go together.

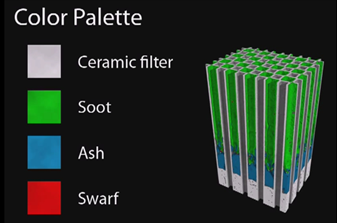

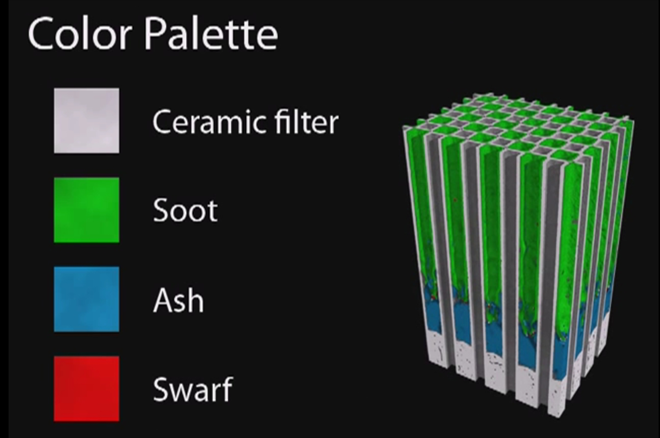

Neutron tomography of a partialy saturated diesel particulate filter (Paul Scherrer Institut) (1834/22)

At this link you can view a video that shows live accumulation of particulate matter like soot into the microporous walls, also soot that is shaked down to the bottom of the cell and the cell is gradually filled up. Metal swarf jamms into the ceramics and remain stuck. Neutronový tomograf - Copyright Paul Scherrer Institut

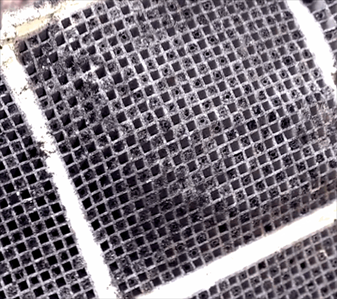

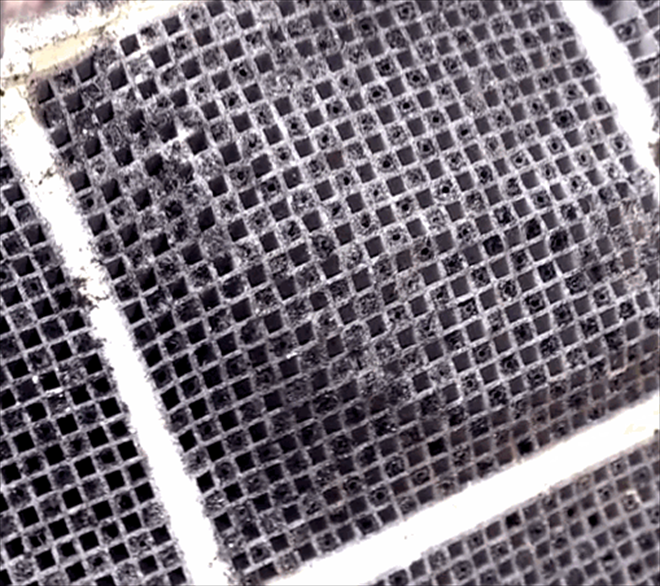

Detail of particulate filter after chemical "wet cleaning" (1834/23)

The picture shows part of particulate filter after a transversal crack. This area after the crack (towards the tailpipe) shows signs that less exhaust gases are flowing and due to this no regeneration occurs. The cells gradually become blocked by soot, the exhaust gases start flowing out of the crack. This exhaust gas leakage during vehicle driving and during regenerations causes that the part of the filter after the crack will not regenerate due to the low level of exhaust gases that are capable to reach that part of the filter. The customer is usually happy that no warning light illuminates after chemical cleaning. It will not take long before the problems reappear.

Contamination with chemical cleaners (only about 15 % of the channels are active) (1834/24)

This vehicle used fuel additives like Liqui Moly, Pro Tec to clean the system and an additive to stop fuel from freezing.Unfortunately these additives were used in random order and thus we don't know if the contamination (85 % of the channels are clogged by a hard material) was caused only by one of these, all of them or everyone of these contributed partially. This is unfortunately, a picture of chemical additives that are added to fuel systems in good faith, but the result is that the DPF filter must be replaced (cannot be cleaned).

Video how a DPF filter works (1834/25)

The DPF filter knowledge in the Czech Republic is very low. There may be other countries behind us, but the majority of Europe is in front us.In order that the vehicle owners are not receiving only information from various so-called experts that make business from removing DPF filters and catalytic converters, we will focus in several short video tutorials on particle filters and later also on SCR systems.

Komentáře (3)

I would greatly appreciate. If you guys can add english subtitles to all your videos. This would make it easier for Service Technicians to understand the content that are located in other part of the countries. Thank you and keep up the great work!

Hi Sandy, sorry for the late response was out of the country for a while. We have some of our videos dubbed. We are having an internal discussion if to continue in dubbing or if subtitles would be enough? Subtitles would be quicker. We had the dubbing done by an external company and that takes time. So would you think that subtitles would be OK?

Toto je odpověď na komentář ( 1 )Thank you for getting back to me and yes subtitles would be great. I would really appreciate you can make that happen. Thank you again!

Toto je odpověď na komentář ( 2 )