Most of you know this scenario when the customer asks for a cheaper part alternative. This is when the problem begins. The internet offers many suppliers and allows customers to easily browse for options. Low quality parts are offered through the complete wide range of parts suppliers and some are strictly refusing any claims. The workshop is in a trap because they have installed something that will either not solve the problem or even aggravate the problem.

The customer returns repeatedly to the workshop, buys useless parts that don't work and thus makes the repair of his vehicle more expensive. Has the customer been warned by somebody? Why should he suspect that such low-quality parts are being offered!

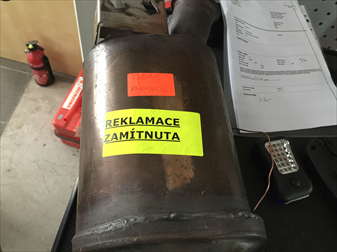

Nonfunctional oxidation catalytic converter on diesel engines with DPF filter can damage the DPF filter or engine! More frequently than ever there are more cases where a low-quality part is installed and after only a few hundred km it can be determined that it's a nonfuctional part worth 250,- Eur and if you add the costs for assembly and disassembly of the part they are costs that the customer has thrown out of the window. FCD.eu is advising all the workshops: "Rely only on verified suppliers that are willing to sort claims. Warn the customer who is supplying his own parts for the repair about the possible consequences and include this in the workshop order!"

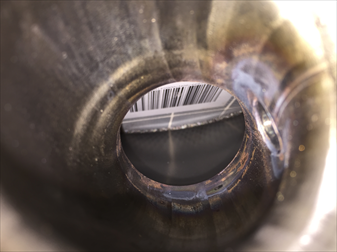

When buying parts pay attention to those that don't have any identification marks and numbers.

Who would expect a sticker inside the filter? Those who don't notice and install the filter with the sticker in place can expect problems during activation of the filter.

With a heat gun heat up the front inlet part of the converter (install an exhaust gas extraction system to the converter outlet side to create a MILD suction effect) and apply a short burst of HC aerosol (start spray, brake cleaner or similar) onto the heated converter. The converter should heat up within a few seconds as a result of a chemical conversion. If the converter begins to "glow" like this it is an indication that a catalytic layer is present. To verify if the converter is capable of reaching the required regeneration temperatures after injection of diesel fuel can only be verified on the vehicle.

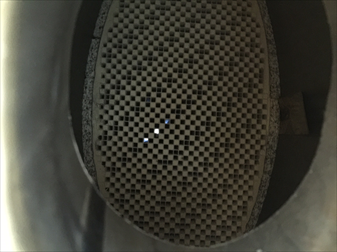

This filter design is intentional and complete fraud from day one. The modification acts as if someone takes a drill and drills a big diameter hole through the entire filter. It doesn't trap the particles, they are emitted into the air and the changed back pressure values can confuse the electronics leading to frequent regeneration and possible engine damage.

Reputable Czech supplier of parts with its own service concept is offering this unbelievable fraud. The lighter coloured channels originally had full end plates, that created pockets for trapping soot. The ceramic end plates were in production replaced by a material that disintegrates after heat is applied (these are the lighter coloured channels). After they disintegrate a wire can be inserted all the way through the channel to the other side. Same result as on the previous picture - Air Pollution and Engine Damage.

From the many years of experience, we can claim that 80 to 90 % of the available chemical agents for cleaning the engine, cleaning the fuel system or cleaning the DPF filter have some negative side effects. So anything you pour into the engine or fuel tank will most probably end up in the DPF filter. This is how a DPF filter looks like after an attempt to clean the DPF filter using chemicals. The result is that 80% of the micropores are blocked, engine oil is diluted by diesel fuel.

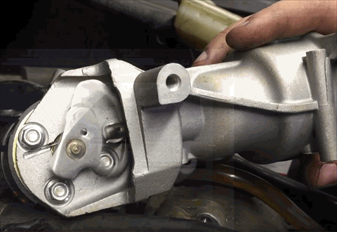

Comparing electronic components visually from the outside is not enough. In this case, we performed an actuator test before installing the component and discovered vibrations during operation. The manufacturers of such low-quality replacement parts are not paying such attention to the used electric motors, return springs as the manufacturer of an OEM part.

After the vehicle accumulated high mileage, the DPF filter became naturally blocked by high ash content. There is not enough space for soot and regeneration cycles repeated more frequently. The DPF filter was cleaned by pulsations from the back side under high temperatures. After the cleaned filter was reinstalled the engine ECU didn't like the dynamic resistance of the microporous walls that were contaminated by the chemicals. This activated regeneration every 80 km (10x more frequently). The engine ECU was constantly interpreting the high resistance as that the filter is saturated by soot even though the actual soot content was almost zero. Repaired by installing a new original filter.

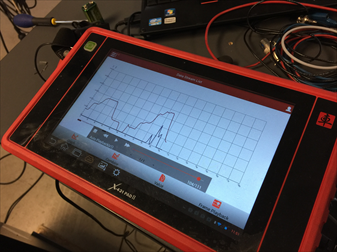

It is not easy to understand when someone buys a new part that it could be "defective". Also, the classification of the problem is not that straight forward. Usually, it's not a clear failure of the part but we can say that the parts output values have unusual behaviour. On this image of the traces, the red trace is engine RPM and the second blue trace is the voltage value of the differential pressure sensor in front of and behind the DPF filter. The traces should have a similar shape because the pressure should be rising proportionally with the engine RPM. How should the engine ECU respond to such behaviour where at first the sensor is not showing any backpressure and then it suddenly jumps to a high value and then disappears again?

Many of the low-quality parts are hard to detect. This is not the case.

The DPS sensor distributed by an aftermarket parts supplier has no ID markings on it, apart from Made in Italy. This part was purchased and not much cheaper than a OEM part in good faith as an replacement part. This No Name part has actually cost the owner over half a year trying to find the fault and over 2 000 Eur in labour and parts costs in various workshops without fixing the problem. The combination of two factors was the cause of this cars problems. The first issue is that this No Name DPS sensor doesn't comply with the basic parameters required to measure differential pressure and the second issue is the Scan Tools diagnostics software that offers incomplete information related to the DPF system for MY 2006-2010 cars.

Komentáře (0)

Vložit soubor