- 2 Aktuální žádosti o pomoc Poraďte svým kolegům

- Požádejte o pomoc

- Podejte dotaz do fóra

- Vložit hotový případ

- LOG Decoder

Žádost o pomoc

Žádost o pomoc vyplňte, pokud máte rozpracovaný diagnostický případ na konkrétním vozidle, u kterého potřebujete pomoci zjistit skutečnou příčinu závady.

Pro naše nekonvenční metody je nutný základ znalostí a mít vlastní vybavení minimálně pro "logování", lépe však osciloskop. Nejlepší přípravou pro práci jsou naše videoškolení a akademie.

Jak to funguje?

Do online formuláře v jednotlivých krocích vyplníte všechny důležité údaje k případu a poté Vám ostatní registrovaní diagnostici poradí v komentářích*.

Supervizor a moderátoři FCD.eu samozřejmě vše doplňují a kontrolují správnost informací, aby cesta vedla ke správnému cíli.

Požádat o pomocDiagnostický případ

AdBlue – restricted driving range

Informace o vozidle

| VIN: | WAUZZZF4XHA015331 |

| Výrobce: | Audi |

| Model: | A4 |

| Rok výroby: | 2016 |

| Kód motoru: | 2,0 TDI CR/Ultra |

| Typ motoru: | DEUA |

| Výkon (kW): | 110 kW |

| Převodovka: | Automatická |

| Palivo: | Diesel |

| Najeto: | 283 555 km |

Jak se závada projevuje

Nefunguje / funguje nesprávně. A fault message on the instrument cluster for the AdBlue system with reduced range. At the same time, a fault related to AdBlue system P204F is logged in the control unit.

Jak často se závada projevuje

- Trvale přítomná závada.

-

Sporadicky / za specifických podmínek.

- Za jiných podmínek. During driving (longer) when the unit performs a self-test.

V jakém systému se závada vyskytuje

- Motoru.

- během jízdy

- [P204F] Reductant System Performance Bank 1: Malfunction

- trvalá závada

- sporadická závada

Doposud provedeno bez úspěchu

DPF cleaningReplacement of LP EGR cooler + EGR

Exhaust gas pressure sensor replacement

Replacement of urea for new

Reset of SCR adaptation values

Reset AdBlue level

AdBlue quantity test

AdBlue injector condition check

Check the pressure of reducing agent

Check for leaks

DPF and regeneration check

Update software to the latest version

Závěr

VOZIDLO JSEM OPRAVILAfter the first job order, I read the fault memory where fault P204F was logged. The customer initially arrived saying that he feels the vehicle is not regenerating.

An initial wide log was performed first, which turned out to be perfect. Next, a specific LOG was performed focusing on the regeneration. The regeneration proceeded with sufficient temperatures.

During the first 200 km or so the vehicle operated without re-logging the fault. During this time, the AdBlue injector condition was checked (cleaning was done), urea transport, pressure etc. Everything appeared to be in good order.

A software update was done, with an attempt to follow the TPI instructions. As per Audi's recommendation, the NOx sensor needs to be replaced.

Information on what the control unit uses to evaluate that the fault code P204F should be logged was missing, and the manufacturer couldn't answer what the unit scans and from what it concludes low efficiency.

Fortunately, thanks to the help of FCD members, we received information on how the unit performs the test. We managed to capture this moment with the LOG and found that even though the unit doesn't have data from the second NOx sensor (behind the DPF), it can perform a test that returns NOx-free exhaust gas to the sensor behind the turbo and compares the expected and actual NOx content. If the values are different, it will log the DTC code P204F.

We checked the urea delivery system again. During this check, we found again that the injector wasn't delivering the urea dose. Therefore, after an agreement with the customer, the injector was replaced. The replacement eliminated the problem of the intermittent failure to inject urea, but we didn't eliminate the error message.

This was followed by further test runs focused on a specific SCR conversion test. As we cannot diagnose the NOx sensor itself, we used sample data from a similar car with a similar engine. We compared the NOx data from these two cars and agreed that both engines produce similar amounts of NOx, thus ruling out a NOx sensor fault.

The last piece of the puzzle was the SCR DPF/KAT itself, which was supposed to reduce NOx with urea. The only way to check if it was working properly was to use an exhaust gas analyser because it's the only tool that can measure NO levels. We carried out a LOG recording with the analyser while driving and the NO readings from the analyser were equal to the NOx sensor on the car, even during the urea injection phase into the exhaust and at operating temperatures.

Thus, the accused for the inefficiency of P204F was identified as the SCR DPF/KAT itself, which isn't capable of the chemical reaction NOx + NH3 -> N + H2O (in simple terms).

This component was chemically cleaned just prior to the occurrence of the P204F fault, which may be one of the causes. The SCR layer on the DPF may have degraded due to the chemicals.

Complete part (KAT+SCR+DPF) with OEM number: 04L131670SX can be ordered as an original part for: approx. 2 900 EUR or as an aftermarket part for approx. 1 875 EUR.

Obrázky, fotografie a soubory

AUTHORISED DEALER NO WAY! Audi A4 B9 2.0 TDi DEUA 2016 – P204F – SCR/AdBlue - FAULT (15778/1)

In this video, we'll focus on a fault with the SCR system that has given us a lot of trouble. It was a long journey to fix the cause, and we did it ourselves. Along the way, we found out that even the authorised workshops don't know how the systems work and how to repair them. Once again, we encountered unprofessional procedures on the part of the authorised workshop, where we were advised to replace parts that were not defective. The same story is being repeated more and more often.That's why we made another video detailing how we arrived at the cause of the limited range message due to a fault in the AdBlue system. It wasn't easy, but we walked away as winners and gained a lot of experience that we intend to pass on through FCD.eu. So stay tuned!

Links:

Diagnostic story - https://www.fcd.eu/story/15332 (active from 25.5.2023)

Diagnostic e-shop - https://shop.fcd.eu/

Affordable diagnostics with online OEM functions – https://shop.fcd.eu/thinktool-master-x/

Audi A4 DEUA (15778/2)

Illustration imageIntermittent injector seizing (15778/21)

From testing in and out of the vehicle, occasionally, the injector didn't inject urea. For the system to function, it was necessary for the injector to work, so it was replaced.Price of new part - approx. 540 EUR

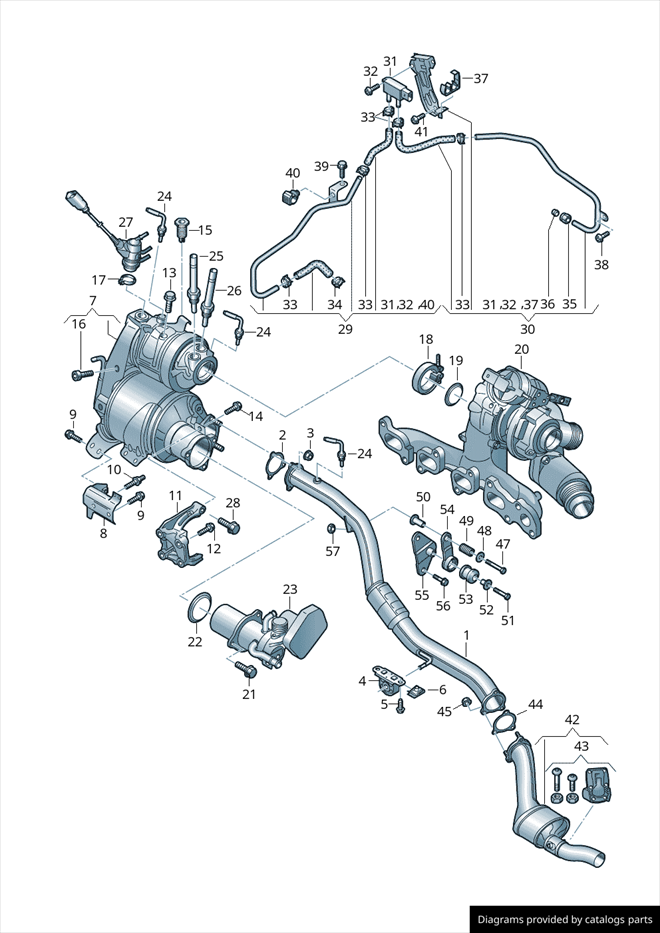

AdBlue fault message (15778/28)

Information about reduced driving rangeComponent breakdown (15778/29)

The whole problem is related with a SCR malfunctionSCR description (15778/30)

Animation describing the chemical reaction and function of the AdBlue SCR system.Old DPF (15778/31)

Defective SCR layer and the oxidation catalyst itself - quite possibly damaged during incorrect cleaning.You can see from the photo that it has been opened up (not original welds), and painted with missing heat shields.

Soubory ke stažení

-

xlsx001_Initial LOG with FCD LOGGER (15778/3).xlsx There was nothing in the initial LOG to suggest a fault related to AdBlueStáhnout soubor

-

xlsx001-1_Initial LOG with the FCD LOGGER (15778/4).xlsx There was nothing in the initial LOG to suggest a fault related to AdBlue.Stáhnout soubor

-

xlsx002_Regeneration LOG (15778/5).xlsx The LOG focused on the ability to regenerate came out as faultless, the regeneration was successful with a temperature of over 700°C for the DPF, reducing backpressure and clogging.Stáhnout soubor

-

txtDTC LOG (15778/6).txt The fault was stored in the engine control unit and cleared - test drive approximately 150km without fault activation.Stáhnout soubor

-

txtFault code in EOBD - pending (15778/7).txt The fault code stored by the EOBDII protocol – P204F – pendingStáhnout soubor

-

txtReadiness code (15778/8).txt The LOG is recorded before all the readiness codes are completed. After deleting the fault from the engine ECU and the EOBDII log, where all the readiness codes have been completed EXCEPT for "Heated catalyst monitoring: Failed or Incomplete".Stáhnout soubor

-

xlsx003_Motorway driving without fault logging (15778/9).xlsx At this point everything seems to be operating as normal, standard NOx levels, standard urea injection behaviour. There's nothing to indicate a malfunction.Stáhnout soubor

-

docxTPI2040064/15 (15778/10).docx TPI information related to the fault:Stáhnout soubor

https://comm related to the unity.dieselschrauber.org/viewtopic.php?t=31284 -

pdfTPI TPI2045062_3 – one of the possible fault causes (15778/11).pdf If the P204F fault still doesn't occur, you should follow this TPI and delete the range message.Stáhnout soubor

-

xlsx004_Motorway driving without logging fault (15778/12).xlsx Once the CAT and DPF temperatures are reached, AdBlue injection is active and injection is occurring, as can be recognized in the urea pressure drops.Stáhnout soubor

The NOx content on the sensor is standard when compared to another vehicle. Unfortunately, there is no second NOx sensor, so it's impossible to determine if the NOx conversion is occurring correctly.

The test drive is without a recorded DTC. -

xlsx005_Motorway driving without stored DTC – different vehicle Škoda Superb DFCA (15778/13).xlsx Driving log using the same system, the NOx values are similar, so there is no reason to think that the Audi engine produces more NOx than usual. The NOx sensor malfunction could be questioned.Stáhnout soubor

The whole system works as expected, and there is no reason to look for the cause of the P204F fault message anywhere other than the SCR system itself. -

mwfUrea injector control waveform (15778/14).mwf Standard waveform, no electrical fault or mechanical damage to the valve.Stáhnout soubor

-

xlsx006_LOG_Suspecting no injection of AdBlue (15778/15).xlsx Looking carefully at the graphs, it appears that in some places, despite injector activation, there is no pressure drop, hence the suspicion of intermittent non-injection of urea.Stáhnout soubor

-

mp4Inspection of the injector by VCDS and mechanical non-injection (15778/16).mp4 It turned out that just after the test drive, when it was suspected that the injector might not be injecting, the injector wasn't, in fact, injecting urea.Stáhnout soubor

The injector was disassembled and tested on the test bench, where it successfully started working. Therefore, it was returned to the vehicle, where it didn't stay for long and was eventually replaced with a new one because it was occasionally not working. -

CSVVCDS SCR metering quantity test (15778/17).CSV The injector doesn't inject mechanically. The pressure is sufficient - measured with our own pressure gauge.Stáhnout soubor

-

mwf002_Old injector (15778/18).mwf You can't see any difference on the oscilloscope whether the injector is injecting. This recording is from an old injector when it wasn't mechanically injecting.Stáhnout soubor

-

mwf001_New injector (15778/19).mwf You can't tell the difference on the oscilloscope whether the injector is injecting or not. This recording is from a new injector at the point when it was mechanically injecting.Stáhnout soubor

-

xlsx007_Test drive with old injector + storing of DTC + efficiency test (15778/20).xlsx The captured point of doing the efficiency test while driving, at the same time it looks like the injector isn't relieving much pressure. Fault code P204F. Old injector.Stáhnout soubor

The location of the likely SCR efficiency test is highlighted in the log. -

MOVDefective AdBlue injector (15778/22).MOV Intermittent AdBlue injector not injectingStáhnout soubor

-

xlsx008_Test drive with new injector without fault code recording and without test. (15778/23).xlsx During the test drive, everything appears to be working correctly including injection, but the test hasn't been carried out. So we cannot determine if the fault has been fixed by replacing the injector.Stáhnout soubor

-

xlsxLOG recording point when the fault code P204F was stored. Through the self-test of the control unit (15778/24).xlsx The recorded moment when the unit performed the self-test by closing the exhaust flap, opening the low-pressure EGR valve, and closing the intake flap and the high-pressure EGR valve. The actual NOx value is higher than expected. These values reveal the location where the fault was recorded:Stáhnout soubor

Nox Sens. Dwnstrm. SCR Cat Conv, Nox Conc. According To Diagnosis Nox SWORD

Nox Sens. Dwnstrm. SCR Cat Conv, Nox Conc. Limit Value Diagnosis Nox SWORD

I used these values as a base and found other connections in the log. It was always the same test in deceleration. Verified several times. So now we know how the unit tests the effectiveness of the SCR system. -

txtEverything is probably connected with the readiness codes (15778/25).txt Catalyst monitoring: Failed or IncompleteStáhnout soubor

Heated catalyst monitoring: Failed or Incomplete -

xlsx009_LOG_GAS_NOX (15778/26).xlsx The values on the NOX sensor and the real NO coming from the exhaust are identical. The urea injection is active only about 5%. Nevertheless, I expect the NO value to be half or a third of that since NOx is made up of NO2 and NO. Despite the correct OXI-CAT temperature, there was a high NO reading at the outlet of the exhaust, and it was almost equal to what the NOx sensor was showing.Stáhnout soubor

-

xlsxDPF condition – has reasonable leak-tightness (15778/27).xlsx You could find more leakproof. A completely leakproof filter emits less than 1 000PN [1/cm³]Stáhnout soubor

Filters with some mileage will have a limit of 200 000PN [1/cm³]

Anything above 200 000 PN [1/cm³] will cause problems both to the vehicle systems and at the emissions test when the smoke level is measured.

A filter that isn't functioning at all emits above 3M PN [1/cm³]. -

xlsx010_LOG_after_repair (15778/32).xlsx Final LOG during which the unit tested the SCR efficiency - all good!Stáhnout soubor

Komentáře (0)