Using this case study, I will describe why the FCD Garage decalogue is so successful.

Ideal bargain if you know what you should be looking at. The price was pushed down to approximately 6250 EUR due to high kilometres as a TAXI car, and a problem with the diesel particulate filter's failure (oversaturated). The DPF problem was indicated by a burnt differential pressure sensor. Inspection of the exhaust revealed that the car had never been driven without the filter (nice clean sheet metal without any signs of soot).

First, the filter was cleaned, and the burnt sensor was replaced, but the car jerked as before with the clogged filter. The car occasionally jerks violently and then drives normally again as if nothing had happened.

The technician that was called in from the authorised workshop advised replacing the turbo. "The jerking is obviously caused by the turbo, it's even being reported!" After replacing the turbo, the jerking was exactly the same as before its replacement and before the DPF filter was cleaned.

"Let's have a look at the injectors! They have high correction values!" Cleaning didn't help, so new injectors were purchased. That didn't help, and the car continues to jerk.

The second repairer, also from an authorised workshop, was approached and said, "It's the speed sensor, I spotted it in the fault codes!" After replacing the sensor, the car still jerks...

"It's the wiring, the fault must be in the harness! A tricky problem..." The harness was repaired (a new three-wire harness from the control unit to the sensor was installed...). The car keeps on jerking, sometimes after driving 20 km sometimes after 150 km, but then there comes a moment when it starts jerking violently for a while. Then it goes back to normal driving like before.

"It's caused by chiptuning, we have to reflash the ECU and return the OEM software!" The ECU was reflashed with standard software and the jerking is still there.

"Hey, let's change the camshaft speed sensor, maybe that's the cause!" It was replaced, and the car continues to jerk.

"Occasional CAN communication fault codes appear so there could be a problem with the communication lines, this is going to be a nightmare to solve! Because the issue is stored in multiple units..."

The owner stopped trusting his two friends, even though they were knowledgeable, after all, they both worked at authorised dealerships...

"Yes, we've got a spot, a customer has cancelled his appointment, so bring him in."

A carefully written statement is the first step of the DECALOGUE: Exhaust clean, crankcase positive pressure 3 mbar, idle fuel consumption 0.5 L/h with the engine warm. Clear evidence that the engine doesn't have any mechanical issues.

A concern is the inactive Start/Stop system (even though I am not a fan of this system). This is an indication of "modified" software. The modifications can be different and in different places of the software. Well, we'll leave it for later. We're not in a corner yet, and we'll make our first Log recording using our new FCD Logger.

The faith in fault codes has been the same trap for 50 years, and no one has learned the lesson yet across the whole of Europe (this is not just a Czech syndrome). Prof. Matthias Becker of the Technical University of Flensburg assessed the success rate of fault codes in his 2004 study at 55% (Volvo, VW and BMW brand diagnostics were evaluated). This number has stayed the same to this day.

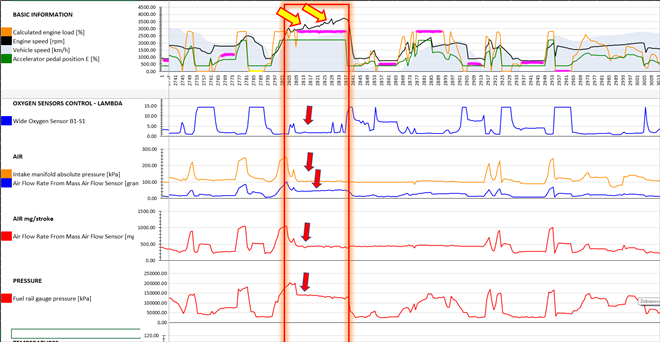

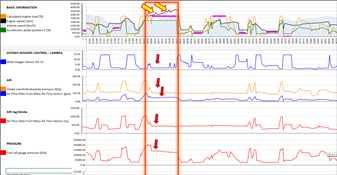

The initial log recorded strong jerking together with active DPF regeneration (which can be recognised by the temperatures in the exhaust). For this reason, I included exhaust backpressure in my "what to monitor" analysis. This would show if there was an internal restriction caused by, for example, a broken silencer baffle. In that case, it could behave like this.

A biscuit and coffee followed by a patient 15 minutes with the FCD Logger recording from the test drive provided a rather hidden clue. The engine rpm trace didn't show drops when the engine was jerking, as expected, but spikes! Completely unexpected but interesting information. What's wrong there???

In addition to the EOBD values from the FCD Logger, 8 values from the signal recorder (TEXVIK) were monitored first: cylinder 1 injection, exhaust pressures (two sensors) and fuel pressure signals in the rail, speed sensors, airflow sensors and the last signal from the Lambda sensor.

How dull is the Group's diagnostics! At the 9-second jerking symptom, the flashing glow system warning light on the instrument cluster warned that the turbocharger boost pressure wasn't achieved! This was true, but the diagnostics missed a much more serious fault. As a result of the micro to millisecond dropouts of the speed sensor signal and crankshaft position, the control unit shut down all injectors for at least 4 engine revolutions! Repeatedly within tens of seconds of each other.

A secondary fault (low turbo pressure) is registered, and VW diagnostics fail to notice the injection dropouts for 4 engine revolutions caused by speed sensor signal distortions?

Clearly. I found out by accident during one of the engine startups. The fault code "P032200 - Ignition/Distributor - Engine Speed Input Circuit - No Signal" only appeared during one prolonged start. But when the engine almost jumps out of the car while driving, the control unit doesn't register the problem.

We know that the speed sensor signal is defective, but we don't know what to replace. Is a wire defective, the control unit, the sensor itself, or signal noise from another external source of magnetic interference?

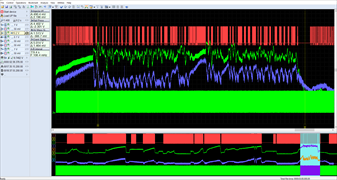

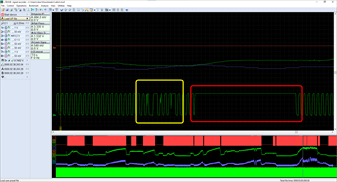

Connecting the three sensor wires at the sensor's connector and the "A" connector of the control unit requires 6 well-connected oscilloscope probes.

In the FCD Academy, we describe how to recognize whether to replace the sensor by disconnecting the connector or by simulating a fault failure.

We at FCD Garage start by recording the customer's statement based on our DECALOGUE. He stated, among other things, that the crankshaft speed sensor had been replaced and the software had been updated to the latest. Neither was true. We then proceeded to read the fault memories of all the control units, check the oil level, emissions, and crankcase positive pressure, view the inside of the tailpipe, test drive the vehicle and record the engine values with the FCD Logger (our modified EOBD log providing a graphic record of all the monitored values).

The FCD Logger scored twice. It captured the bouncing trace of the rpm readings and the fact that all readings in all operating modes over the next hundred kilometres were standard.

By strict adherence to the DECALOGUE, it was impossible not to find the fault. No guesswork. Just facts resulting from predetermined routine steps and procedures. It has worked and will work for everyone. We pledge this with two fingers on our FCD Garage logo!

Just drive twenty to thirty kilometres with the FCD Logger in the diagnostic connector, and it's clear what's happening. In a ring notepad, list what's different when a fault occurs compared to when the car runs normally. The FCD Logger recorded 40 values on the Superb, but 6 were enough to determine the fault.

It takes about two hours to make all the connections for this Multitest.

At the top, severely missing injectors (a consequence of millisecond dropouts of the engine speed signal); below it, second from the top, the rail fuel pressure; third from the top, the airflow sensor signal, the wide green stripe is the crankshaft position signal (the used resolution doesn't allow to see any faults, you have to zoom in twice). Just 9 seconds over 80 to 150 km. Then it stops, and the car drives normally again. Strangely enough: the control unit doesn't log this as a fault, it just records a turbocharger low boost condition error.

The recording indicates that the control unit is functioning correctly, but the sensor isn't. The yellow section indicates micro to millisecond unwanted "LOW" signal dropouts and the red section shows that the AMR sensor misses a few teeth.

The wiring repair kit has yellow wire insulation.

Here's a harness within a harness. The three wires belong to the crankshaft sensor. Someone's been spending a lot of time replacing wires...

The mechanic worked rather clumsily and cut two other wires. It will need to be repaired, too.

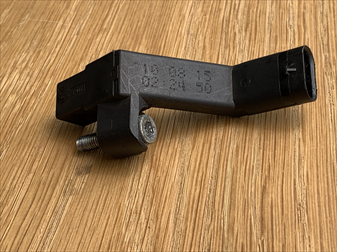

Someone claiming to have replaced the crank sensor wasn't telling the truth. The date of manufacture matches the car's manufacture date. It's difficult to access and requires both good sight and skill to replace. Whether that's why the mechanic gave up and then claimed to have replaced it when it obviously wasn't replaced, we can only speculate.

When you test a car, our App displays all the driving statuses, communications, activity and fault memory contents. The App can also store tags in the log while driving to make it easier to find events in the log.

Komentáře (0)

Vložit soubor