A friend calls up: "I have a Nissan here, but I don't have time to look at it. There are fault codes but the turbocharger is very lazy and the behaviour is very similar to the previous Toyota with the overhauled turbocharger!"

He is very experienced but is getting carried away with a "feeling" that he can see the turbocharger already completely disassembled. This is what 90% of car mechanics do. But this is a mistake. Nothing should be removed or disassembled before everything is not completely verified.

Our detailed troubleshooting has taken us only 20 minutes and we know 100% about almost all the engine subsystems!

Many unwanted steps could have been taken in the case of this Nissan X-Trail. The symptoms that were present have a number of different causes and when the DTC memory is empty the mechanics begin to sort the problem out based on their experience which is almost in 50% cases a mistake! Sometimes this can be a very expensive mistake. You can find the complete case including all the diagnostic steps for your review here Turbocharger – slow boost pressure activation.

Video is available here: https://www.youtube.com/watch?v=EALG8XPZtBs

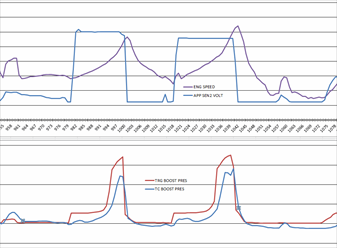

Despite this, the customer arrived with a complaint that it's almost impossible to drive off from a road junction. Since the vehicle is equipped with an automatic transmission the only possibility is to lift the foot from the brake pedal, press the accelerator pedal all the way to the floor and wait several seconds before the vehicle begins to accelerate. We need to find out what is the most probable cause. We insert the OBD module, select the "measured values" and we go for a test drive recording all the values into a LOG.

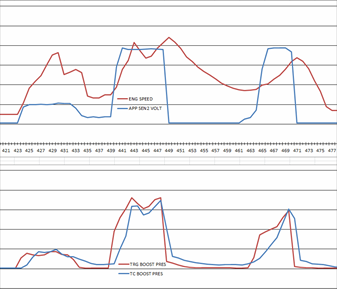

From the LOG graph I can read between the lines three messages: 1) The engine ECU doesn't require higher turbocharger boost pressure during drive off! 2) The boost pressure control allows higher pressure only after a short while (about 3.5 to 4 seconds)! 3) The boost pressure doesn't reach the requested value at any point. At low RPM or at high RPM!

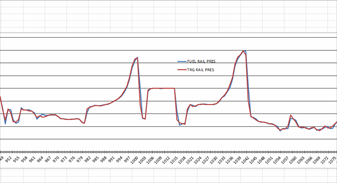

The actual fuel pressure copies exactly the trace of the Target value. With this information, we know that the fuel system is OK and we don't need to do any further test = time saving. Under the general patterns, the following apply " Without air, there is no fuel and without fuel, the turbocharger will not create boost".

After going onto the road it is clear that even with the accelerator pedal on the floor I am restricting the other road users. Above about 2 100 rpm the power starting to pick up. At low RPM there is no power. Power is at higher RPM and the car drives OK even above 3 500 RPM. Driving off from low RPM is very poor. I already know that I don't have to verify the turbocharger, fuel system and fuel injectors. For the following test drive, I will use simulation and disconnect the airflow sensor. I am keen to see and compare the dynamics of ALL the signals in the graphs when the airflow sensor is connected and disconnected. Comparing the signals from both modes should tell me more.

Disconnecting the airflow sensor can be applied on about 95 % of cars. The remaining 5 % of cars will not drive at all with a disconnected airflow sensor and thus this simulation test cannot be applied. With these graphs, we have saved a lot of time and eliminated steps in the wrong direction!

It's quite simple how we arrived at this. The complete diagnostic story with the description of the methods can be studied on the FCD.eu website. (Available only through paid registration.)

Kompletní informace na toto téma

a mnoho dalších informací najdete pod odkazy níže.

Vyzkoušejte si nás nezávazně na 14 dní zdarma.

Vyzkoušet 14 dní zdarma

Komentáře (0)

Vložit soubor