- 2 Aktuální žádosti o pomoc Poraďte svým kolegům

- Požádejte o pomoc

- Podejte dotaz do fóra

- Vložit hotový případ

- LOG Decoder

Žádost o pomoc

Žádost o pomoc vyplňte, pokud máte rozpracovaný diagnostický případ na konkrétním vozidle, u kterého potřebujete pomoci zjistit skutečnou příčinu závady.

Pro naše nekonvenční metody je nutný základ znalostí a mít vlastní vybavení minimálně pro "logování", lépe však osciloskop. Nejlepší přípravou pro práci jsou naše videoškolení a akademie.

Jak to funguje?

Do online formuláře v jednotlivých krocích vyplníte všechny důležité údaje k případu a poté Vám ostatní registrovaní diagnostici poradí v komentářích*.

Supervizor a moderátoři FCD.eu samozřejmě vše doplňují a kontrolují správnost informací, aby cesta vedla ke správnému cíli.

Požádat o pomocDiagnostický případ

Engine vibration and shudder with rattle noise

Informace o vozidle

| VIN: | VSSZZZ1PZ8R026392 |

| Výrobce: | Seat |

| Model: | Leon |

| Rok výroby: | 2007 |

| Kód motoru: | 2,0 TFSI FR (Cupra) |

| Typ motoru: | BWJ |

| Výkon (kW): | 177 kW |

| Převodovka: | Manuální |

| Palivo: | Benzín |

| Najeto: | 69 610 km |

- neukládá žádný chybový kód

Doposud provedeno bez úspěchu

The dual mass flywheel was replaced, complete clutch and the variable timing actuator valve were also replaced.Závěr

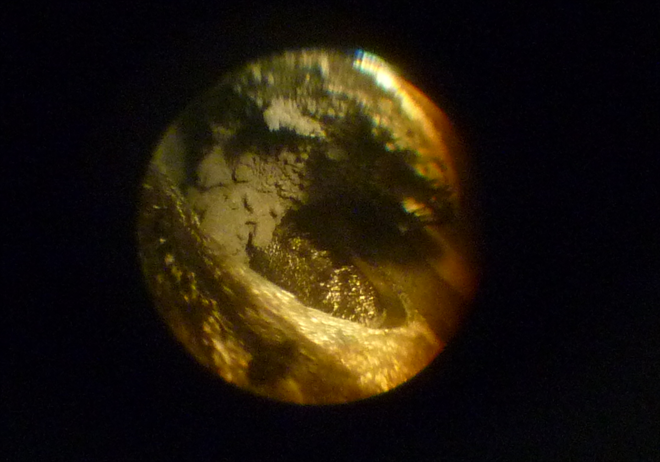

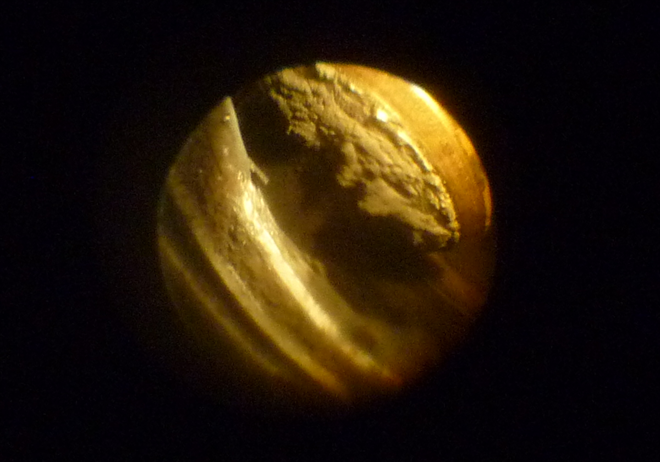

VOZIDLO JSEM NEOPRAVOVALEngine decarbonization was done in the end manually. The engine power was restored. The owner was disappointed by the TFSi engines character that he sold the car immediately despite the fact that he loved the car.

Obrázky, fotografie a soubory

Seat Cupra 2.0 TFSi 177 kW (7112/1)

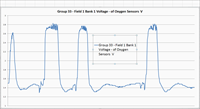

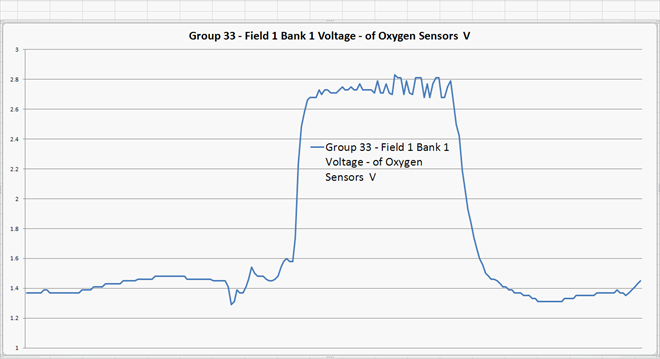

Hot engine misfire monitoring (7112/2)

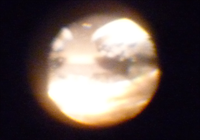

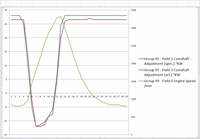

After the engine warms up I didn't like the way the engine started and idle. Idle was occasionally irregular with vibrations. The engine hesitated to accelerate from idle following previous deceleration and this acceleration was accompanied by a rattle noise. I was thinking this rattle noise could be caused by rapid openning of the throttle valve whne trying to save the engine from stalling. Usually the engine accelerated OK but once out of 5 to 8 accelerations the response was sluggish.The engine ECU was monitoring engine misfires at idle, that were more frequent than on the picture but nevertheless were quite high for this engine.

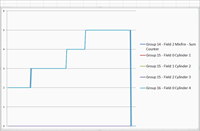

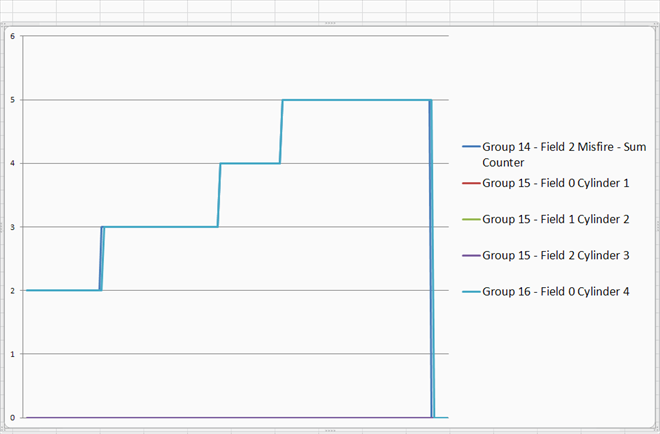

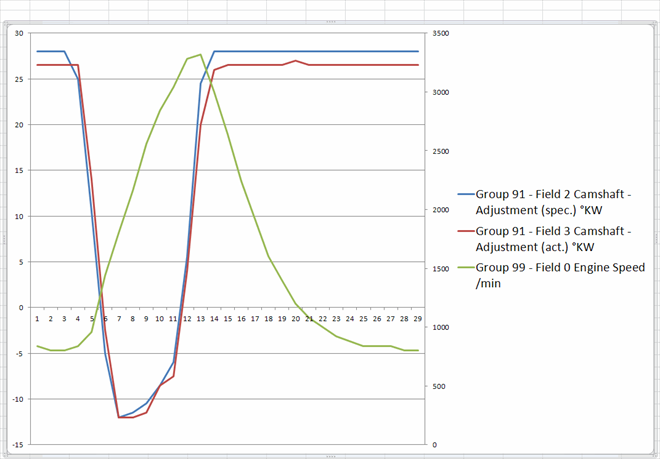

Individual cylinder misfire (Turbo - LOG) from OBD connector (7112/3)

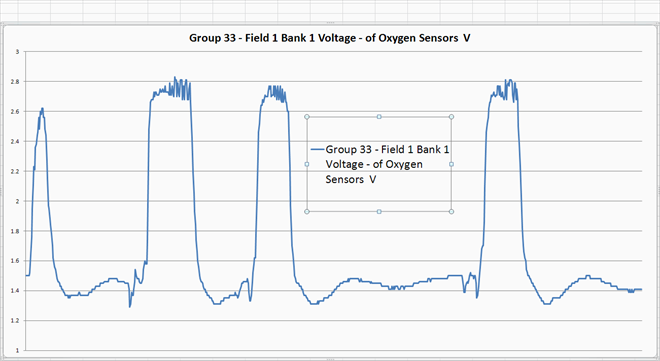

Even without using an oscilloscope I could see on the measured voltage on channel 33 (Lambda sensor voltage) oxygen shocks showing differences in oxygen contents in individual cylinders. I could tell that the A/F mixture wasn't burning correctly by hearing a flapping noise in the exhaust (in particular during acceleration).Note: Some modern engine ECUs allow to increase the logging speed up to 4 times or even faster. In such cases if you are logging only one parameter the grapics can capture the oxygen shocks and you do not need to connect and use an oscilloscope.

Komentáře (0)